Effluent Disinfection

Daro UV Systems has been a trusted partner designing, manufacturing and successfully delivering UV disinfection solutions for water, including effluent water, for over 40 years.

We source as many of the materials and components from the UK as possible; this keeps our supply chain short and manageable; to provide you with a reliable service.

Our experts have extensive knowledge and expertise in providing cost-effective, reliable, fast, chemical-free UV water treatments in UV disinfection solutions for the commercial treatment of effluent water for water companies across the UK.

Wastewater from homes, hospitality, industry and agriculture must be treated before being released into the environment. Human, industrial and agricultural waste contains harmful bacterial, nitrogen compounds, fertilisers or pesticides and other toxic waste that needs to be cleaned.

Once the sewage sludge is digested anaerobically the effluent water must be treated to make it safe.

Effluence UV Water Treatment Systems

The team at Daro UV are experts in chemical-free, environmentally friendly effluent water disinfection.

Proven in the supply of large municipal schemes, and preferred by environmentalists, safe, non -chemical UV disinfection has brought major benefits to rivers and coastal discharges. UV disinfection works through the action of germicidal light, which attacks the genetic structure of microorganisms, achieving a fast and effective destruction of pathogens without the need of a residence tank.

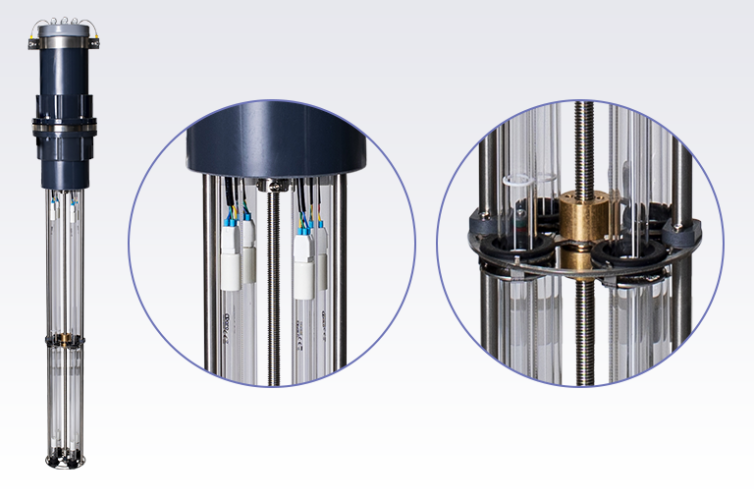

UV lamps are mounted in UV transmitting quartz glass sleeves, which provide an electrical safety barrier between the lamp and effluent. These are immersed in the full flow of the effluent discharge, after the pre-treatment stage.

During use, the quartz sleeves become fouled and need to be cleaned. Excess heat generated by the lamps bakes deposits meaning more frequent cleaning is necessary. Historically, cleaning relied on either manual removal of the unit, and the use of acid baths or, by ineffective mechanical systems which still need periodic acid polishing to prevent long-term, cumulative build up. The use of aggressive chemicals to clean the lamp sleeves is undesirable, particularly on domestic or remote/unmanned sites with the added complication of chemical transportation and storage. The regular removal of the lamp assembly also increases the possible risk of damage to the lamp assembly.

Therefore, the ideal effluent disinfection solution is to provide a reliable cleaning method in situ, without having to remove the lamp modules, and better still, one that is fully automatic. Daro UV Systems has developed an effective self-cleaning system that is simple to install and so reliable in operation that it is particularly suited to domestic or unmanned schemes.

Effective Self-Cleaning System

The EFF range from Daro UV Systems features an automatic wiping system developed specifically for use in heavily contaminated fluid streams. Using an effective two-stage cleaning system long term tests have proven the module does not require acid polishing or alternative backup cleaning. The UV lamp module is also compact and can be handled by one person when required. It fits into a “chamber” compatible with proprietary soil pipe fittings. Other pipe work formats are available allowing the unit to be installed in pumped, gravity fed, RBC (digester units), BAFF units or can be retrofit into existing solutions.

The mechanical action of wiping contaminants from the UV sleeve is a proven method of removing any solids, as has been proven in many large municipal installations globally.

In our own exacting tests, we have found that effluent solids will adhere to any surface including glass and Teflon® – therefore a mechanical wiping system is considered to be by far the best choice.

Configurations and Flexibility

Effluent disinfection systems can be configured in a variety of formats for new sites, retrofit or OEM markets. Larger multiple-lamp estates may also be custom designed for built in or skid packages. Daro UV Systems effluent-treatment units suit flow rates from one m³/hr upwards. This is achieved by using one of two standard lamp modules which can be expanded; either by increased lamp power or by adding extra lamp modules. Larger systems may be configured from a 10 lamp 10m³/hr standard module in single or multiple system, or to specification in larger bespoke formats.

Simple to install

The Daro UV Systems range has been specifically designed to simplify installation and minimise on-site construction work. The units are located adjacent to the upstream effluent plant and designed to fit in with your existing pipework. Large structures to house the UV units are not required.

Upgradable

Standard units can be upgraded without additional site-works, even if site parameters change. With this flexibility to upgrade treatment capacity, site operators have confidence and peace of mind that the system will cope with future growth in treatment demand. For more information please get in touch by phoning 01787 370187 or email info@darouv.co.uk

Minimal Servicing & Maintenance

Our cleaning system are designed with reliability in mind and the only maintenance required is a periodic inspection of the cleaning components, an annual UV lamp change and wiper blade replacement. The units are easily removed for servicing by a single operator and can be serviced on site or in a workshop without major shut down or inconvenience.

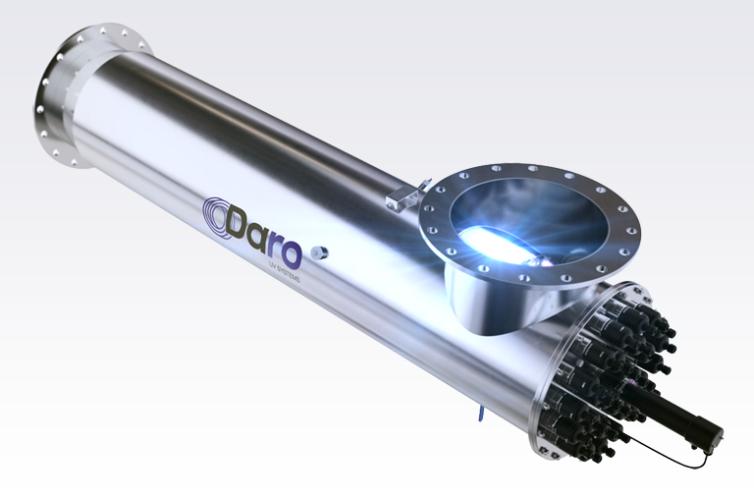

Enclosed Higher-Pressure Systems

Daro UV Systems provides enclosed UV systems for effluent that is pumped under pressure. These systems also include the mechanical wiping system.

Bespoke Manufacturing

All of Daro UV Systems’ products are designed and manufactured in Britain. We regularly scope bespoke system requirements such as different in/outlets, larger flow systems and added telemetry. Please contact us to discuss your specific requirements, we’d be delighted to see how we can help. Call us on 01787 370187 or email info@darouv.co.uk